|

| January 30, 2018 | Volume 14 Issue 04 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Self-programming paint booth scans and delivers

In every industry, products are becoming increasingly customized these days. In the future, production targets may often be set to be characterized by a batch size of one.

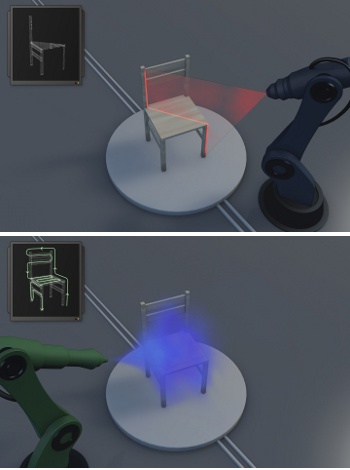

A new system called "SelfPaint" being developed by researchers in Germany and Sweden not only 3D scans an object and spray paints it accurately, but it also optimizes the amount of paint used and the application using multi-physics simulation. [© Photo Fraunhofer FCC]

When it comes to the painting process, however, businesses are still up against some major challenges in this respect. After all, automation and customized paintwork have never exactly gone hand in hand. Only if numerous identical components need to be painted is it worth programming a painting robot to do the job. In many industries, well over half of all components are painted manually, mainly because the extent of variety is simply too great for automation.

But all that may just be about to change.

A new self-programming spray booth painting system offers companies a solution to this problem for the first time -- and opens the door to a wealth of savings along the way. The system is called "SelfPaint," and it was developed by the Fraunhofer Institutes for Manufacturing Engineering and Automation IPA and for Industrial Mathematics ITWM in Germany along with the Fraunhofer-Chalmers Research Centre for Industrial Mathematics FCC in Sweden.

"Our SelfPaint technology enables the automated painting of small batches and even single pieces," says Dr. Oliver Tiedje, IPA group manager and coordinator of the project. "Thanks to this new technology, we save up to 20 percent in paint. This, in turn, reduces solvent emissions by 20 percent. What's more, the booths consume 15 percent less energy and complete the work 5 percent faster than conventional painting processes."

A further benefit is that the automated process also outperforms manual painting operations in terms of reproducibility.

Using simulations to produce perfect paintwork

This new type of automated painting is a five-step process. First, the researchers use robust state-of-the art systems to produce a three-dimensional scan of the component. Data from this scan then forms the basis for a fluid dynamic simulation, where customized software simulates the trajectory of the paint particles and then determines the optimum volume of paint and air needed to achieve the required coating thickness. In the third step, the system uses the simulation data to plan the robot path for the painting process. The painting process itself is then carried out. In the fifth and final step, the quality of the paintwork is inspected to check that the required coating thickness been achieved.

Multi-physics simulation of a high-rotation atomizer with internal charging. In this example, the simulation is being used to calculate the drop trajectory on the car body of a Volvo V60. [© Photo Fraunhofer FCC]

"For the quality-control checks, we apply terahertz technology, in other words a beam of light at a wavelength that lies between microwave and infrared. This enables us to measure wet, colored paint without actually touching it," says Joachim Jonuscheit, deputy department head at Fraunhofer ITWM. The idea is for this whole process to be automated in everyday painting operations. Robots will scan, paint, and check the quality of the paintwork -- all without human intervention.

While researchers from Fraunhofer IPA have been working on coordinating the project and focusing on both the painting technology and the simulation of paint particles close to the atomizer, their colleagues in Sweden have been simulating particle behavior close to the workpiece and working on the automated path planning. More specifically, they are calculating how the droplets of paint move through the air, where they lay down on the target object, and the thickness of the resulting layer of paint.

At Fraunhofer ITWM, researchers are pursuing the 3D-scanning technology and measurement of the coating thickness for quality-control purposes. The individual modules are already complete. Now, the researchers are working to combine the individual steps to form one fully automated process. Expected to be completed in late 2018, the finished prototype aims to help increase the degree of automation and flexibility of painting technology in production.

Source: Fraunhofer ITWM

Published January 2018

Rate this article

View our terms of use and privacy policy